1965 Fender Champ-Amp

The Black-Panel 1960’s Champ-Amp was Fender’s smallest and most simple amp/circuit and was intended for students and amateurs of the time. It was immediately cherished however by a different crowd of professional studio owners and pro guitar players looking to get that cranked-amp, everything-on-ten sound for their albums. Eric Clapton was probably the most famous player associated with this amp. It has an incredible overdrive/fuzz when used with humbuckers with all the controls set at ten - which is my preferred way to play these amps.

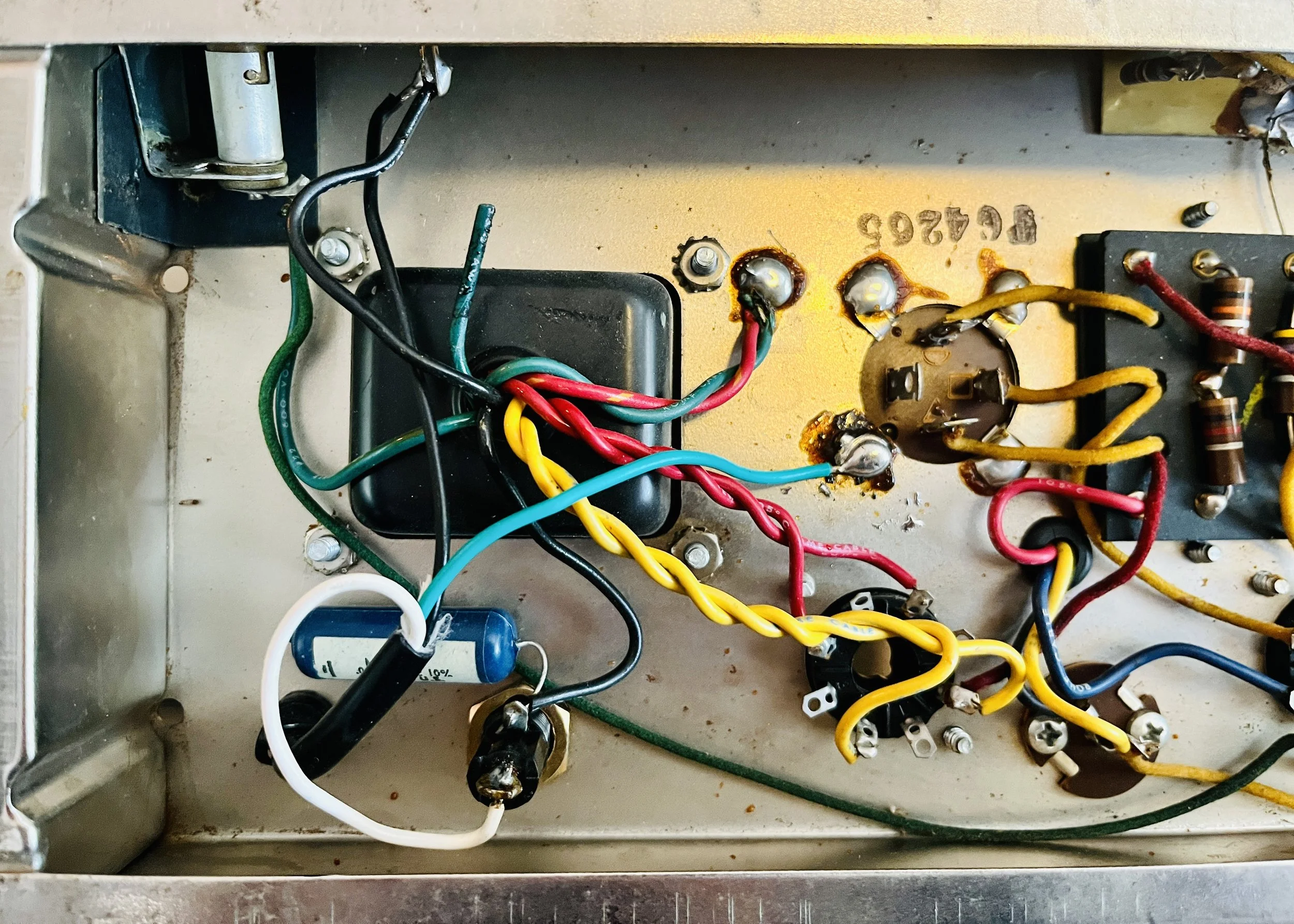

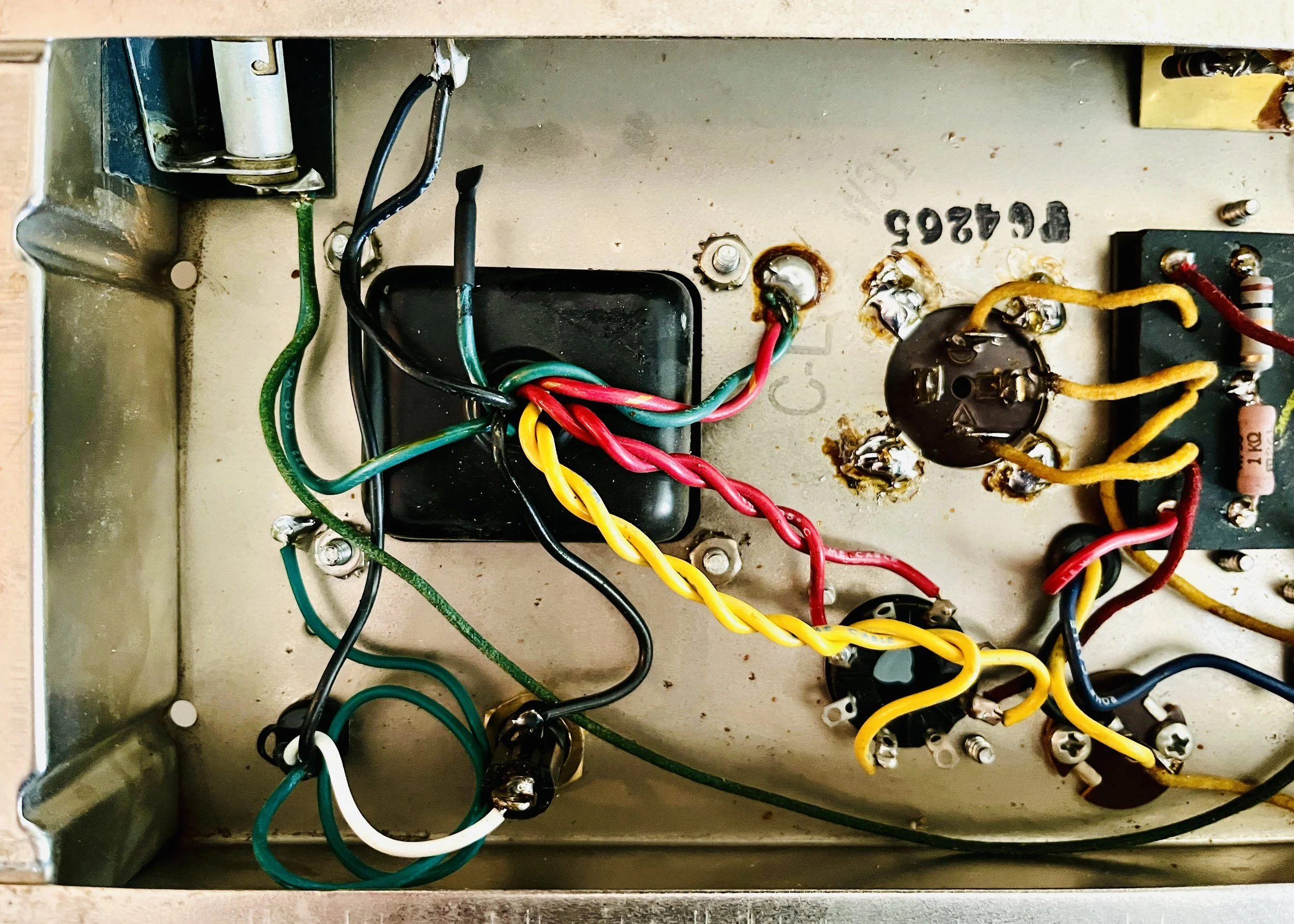

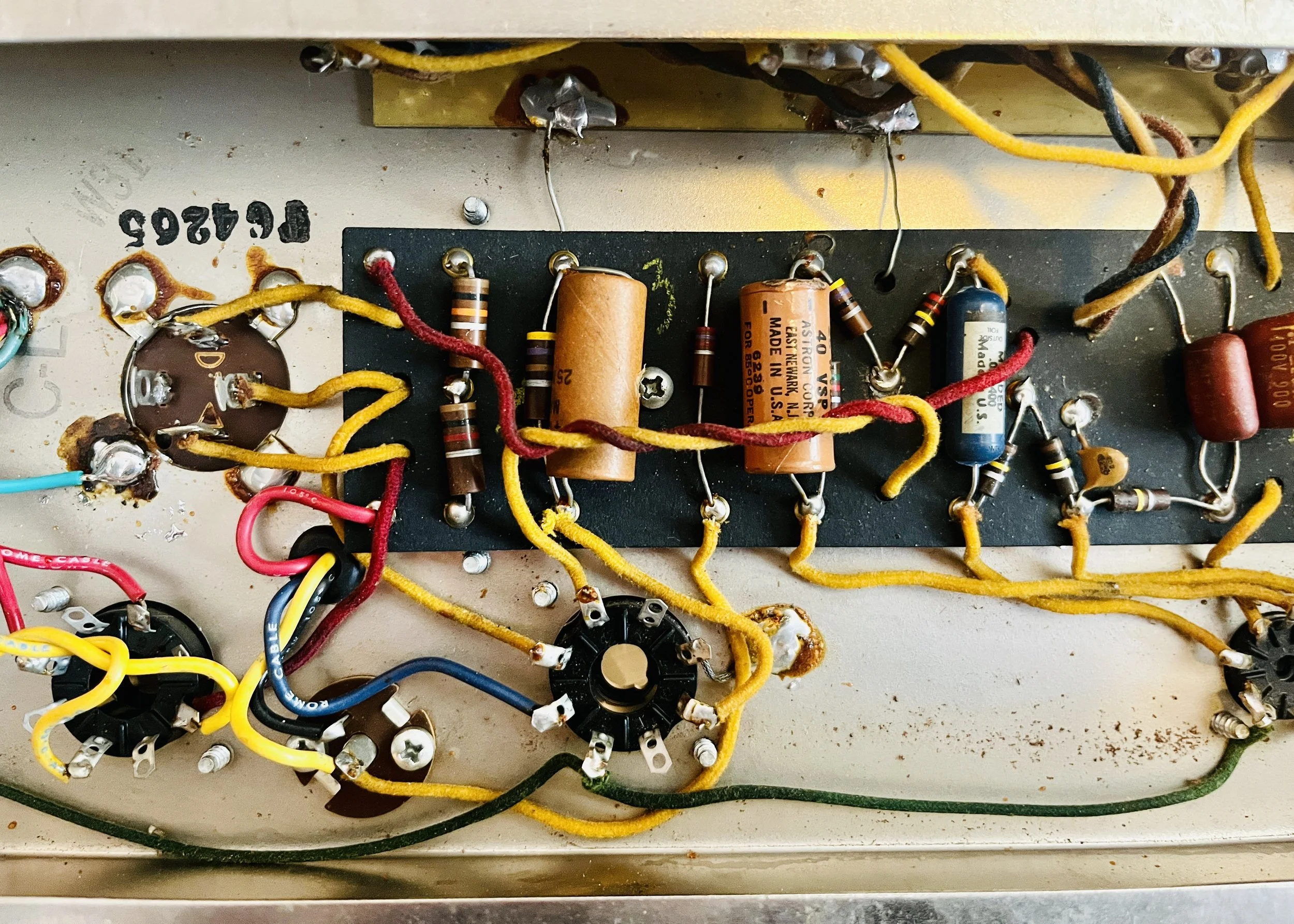

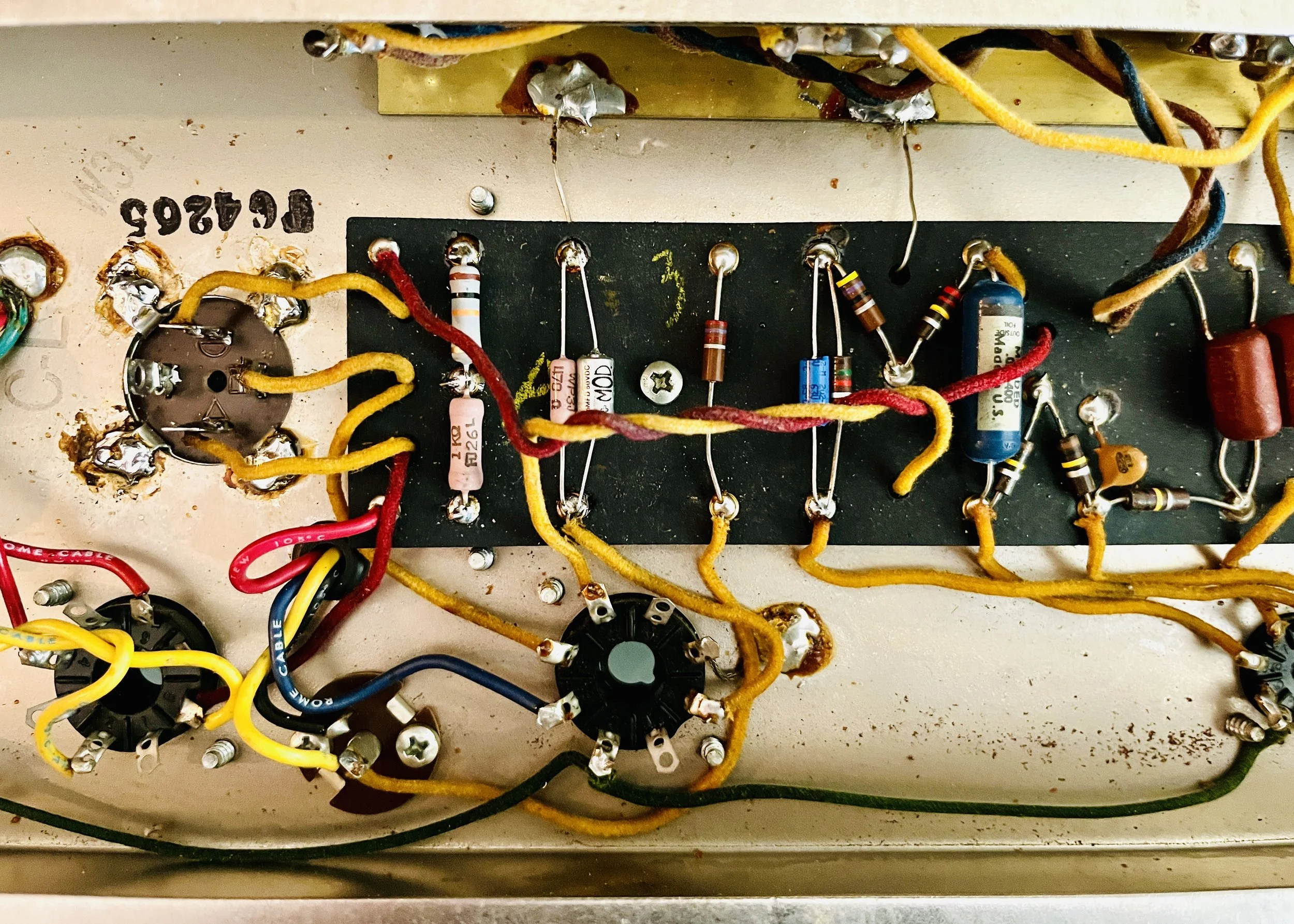

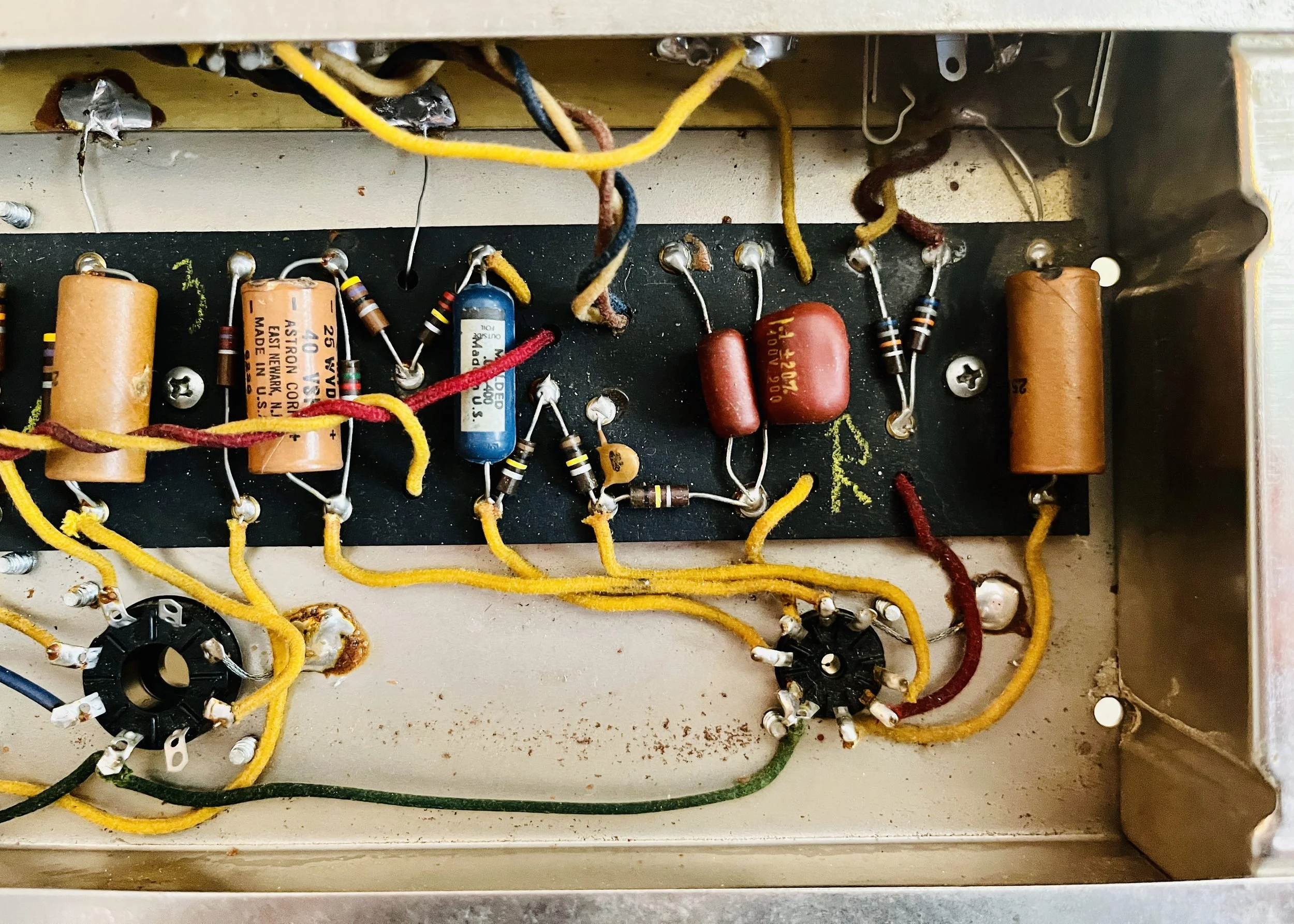

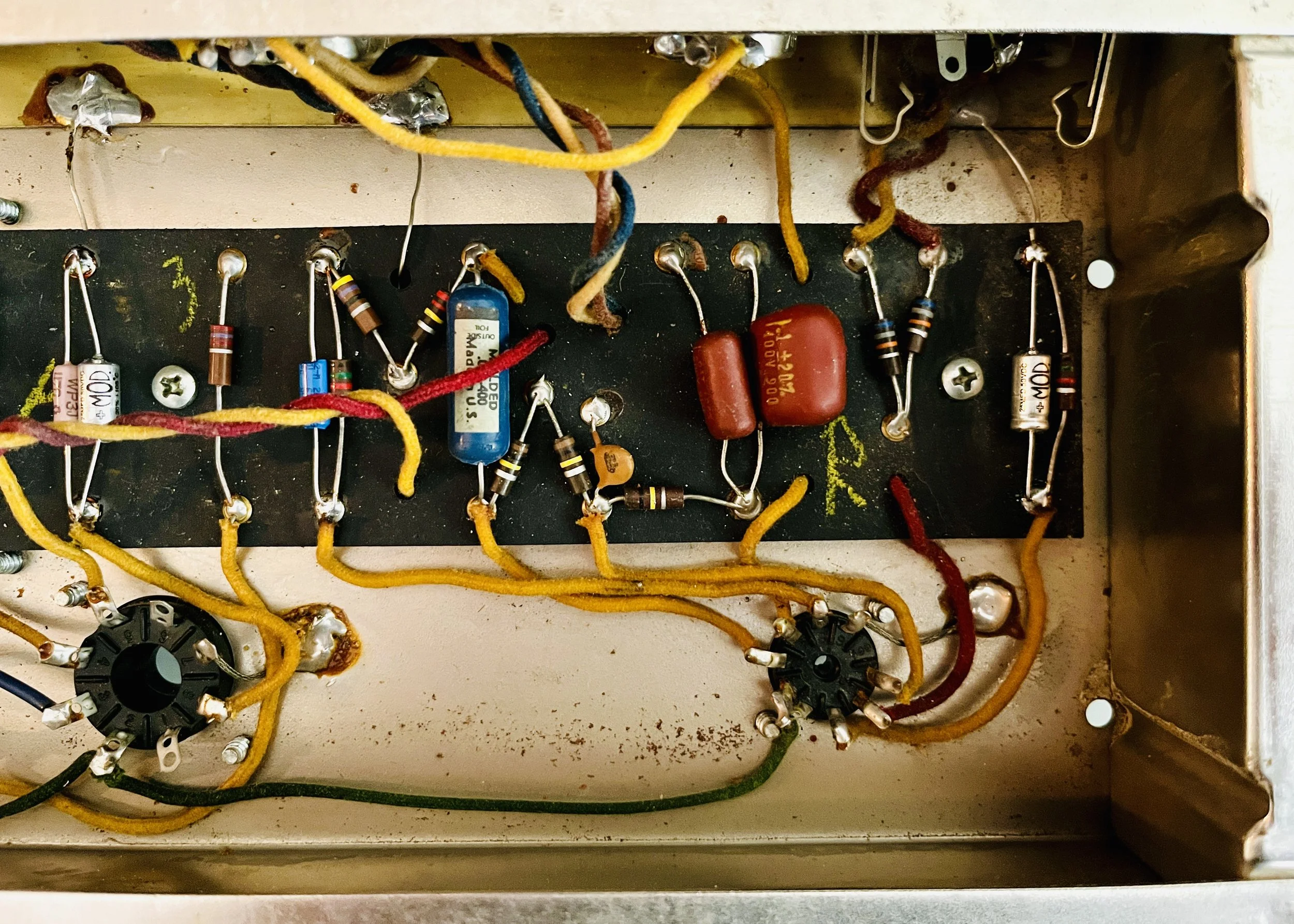

The amp was completely restored. The electrolytic cap can was replaced with a new USA made CE brand exact replica (20uf x 4 @ 475v) for the filter section. The bypass caps were replaced with MOD/Vishay brand electrolytics with upgraded voltage and temperature ratings. New 2 Watt Metal Oxide/5 Watt Cement power dropping resistors were installed for better reliability and lower noise floor. A new 3 Watt 470 ohm Cement Cathode Bias resistor was installed for better reliability and for stability of the 6V6GT bias. A new 3 prong AC cord was installed to replace the old AC cord and the death cap was removed. A new #47 Pilot Light Lamp was installed to replace the #51 bulb that was previously installed - Th #51 bulb is not rated for the correct voltage/current requirements of this circuit.

The original tubes (a mix of NOS and new) did not test good and were all replaced. V1 = NOS Sylvania 12AX7, V2 = NOS JAN/GE 6V6GTY, V3 = NOS RCA 5Y3GT. These tubes were picked for best tone and reliability. The customer wanted all NOS tubes to keep it’s collectors value in place and also because NOS tubes often last 3-5 times the overall service life of new production tubes - Not to mention that they sound amazing, with most people preferring the tone of tubes made before 1988. 1988 is the final year of production from the last Western manufacturer of tubes - It is the year Slyvania closed down their plant in the US. The 6V6GT’s Cathode Bias was set to Factory Spec. The tube sockets were all re-tensioned to stop the tubes from jiggling or falling out while they hang upside down - they also were cleaned with a De-Oxit treatment to prevent noise from corrosion. The pots were sprayed out and the amp was cleaned inside and out.