1966 Fender Vibrolux Reverb

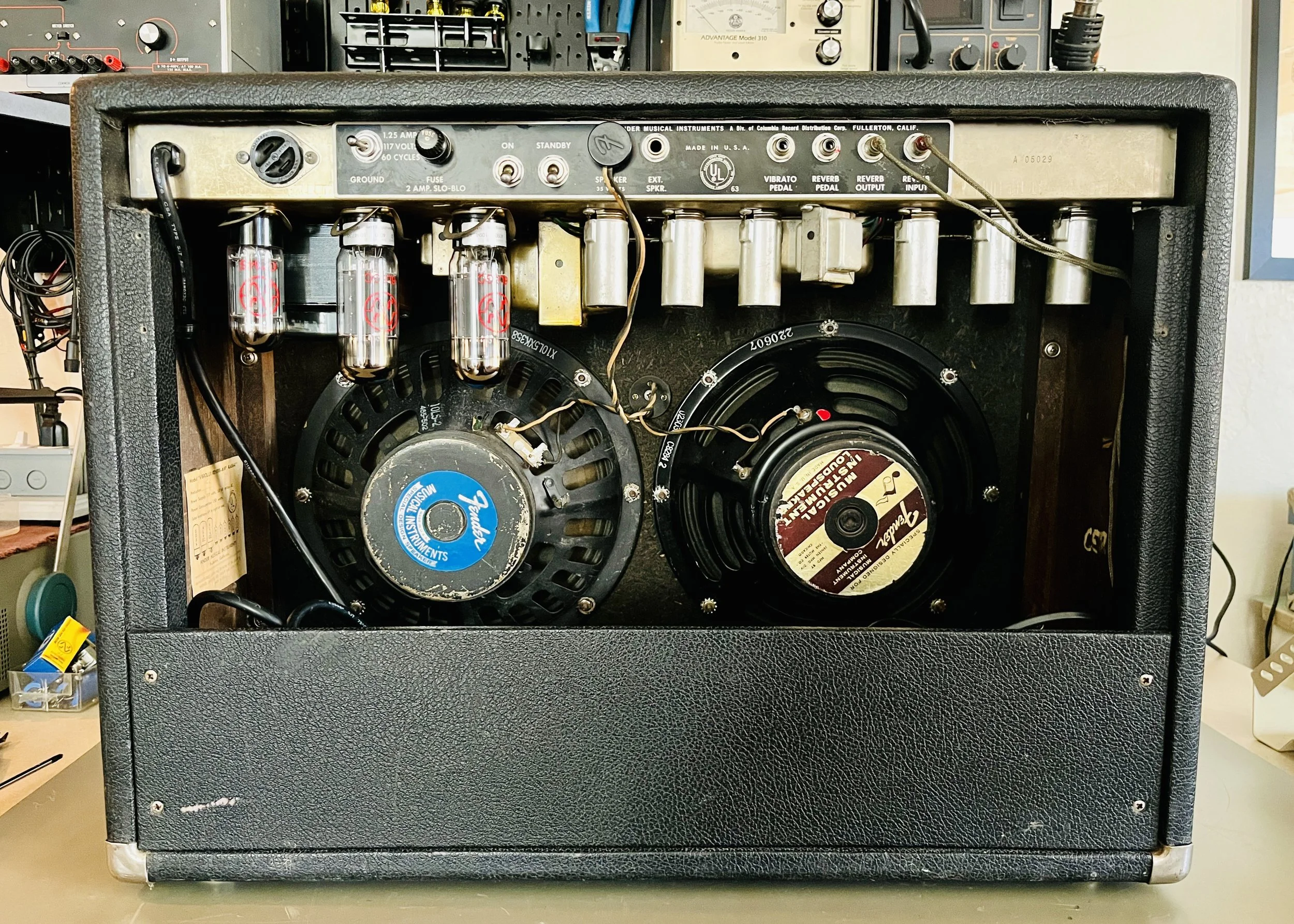

The mid-1960’s Black-Panel Fender Vibrolux Reverb was manufactured between 1964-1967 and is one of the rarer and most sought after Fender amps made. Coming in at 35 watts of power with two 10” speakers and the standard Black-Panel Reverb/Tremolo effects, The Vibrolux Reverb sits in a pleasing middle ground tonally between the more famous Deluxe Reverb and the Pro Reverb. It has more headroom and volume to keep up with a full band compared to the Deluxe, but not as deafeningly loud as the Pro can be. This amp excels at studio work or live settings equally, it’s smaller 10” speakers giving it a faster, snappier attack, and tighter bass compared to many Fender amps. If you are lucky enough to come across one of these, take the time to play it, and it will become obvious why they are so collectible. Notable users include: Richie Kotzen.

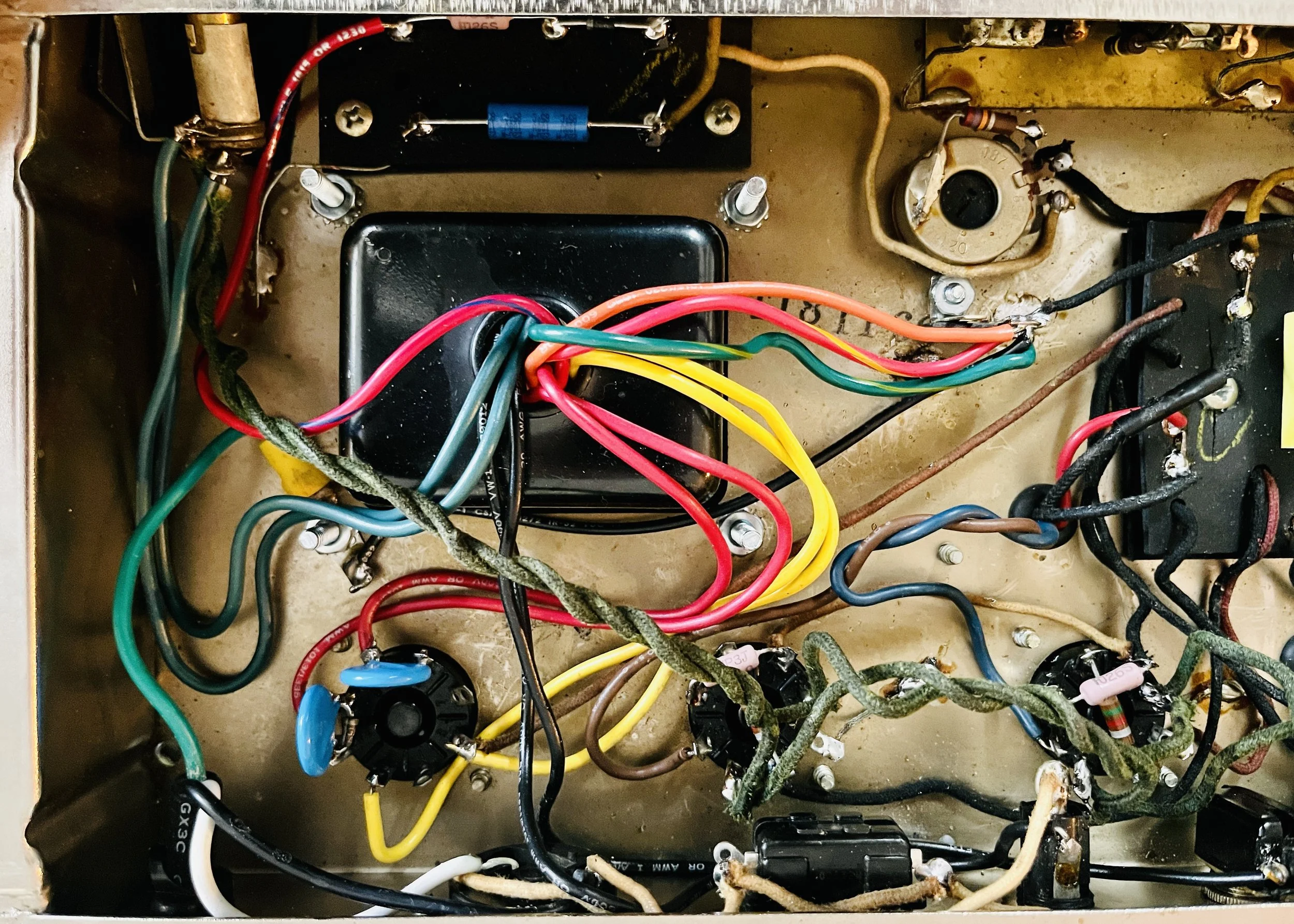

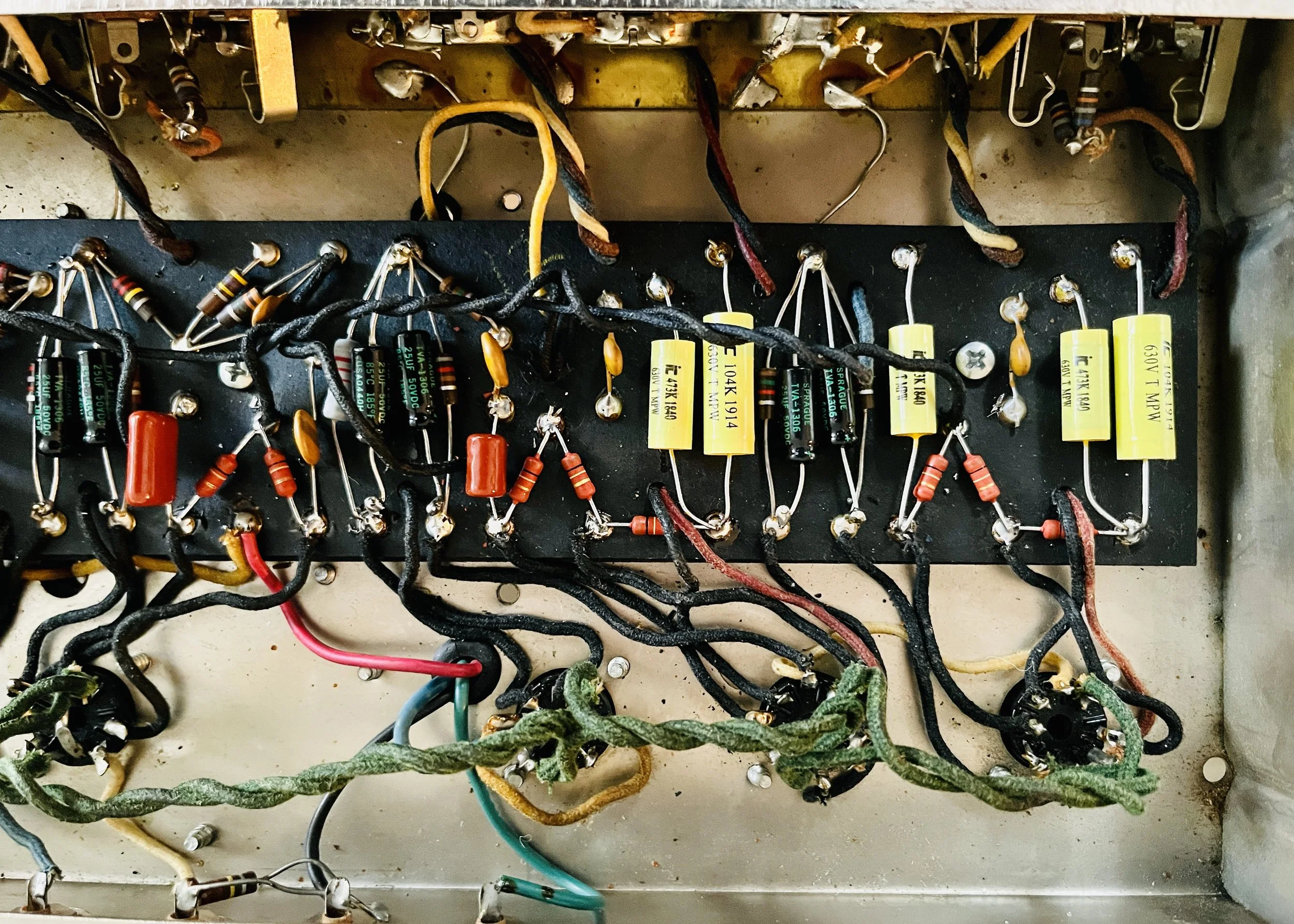

This amp came in to my shop having had been worked on in the past - quite a lot of work actually. The amp already had a complete cap job (both electrolytic and film), re-tube, power transformer replacement, and a new reverb tank. The cap job was over two decades old however and a good amount of preventative maintenance was left undone. The electrolytics were past their prime and the lack of proper filtering was causing noise issues with 60-cycle hum. This was severely aggravated by the improper wiring of the power transformer, leaving no center tap or ground reference for the 6.3VAC heater lines. The bypass caps all tested good and were left in place along with the modern film caps - these things were both installed correctly by the precious tech. This one needed a partial restoration including an electrolytic cap job in the filter section, modification to the filter circuit, new power/plate/screen/misc resistors, re-wiring of the heater circuit, mods to the rectifier and reverb circuit, new diodes, new hardware, and cleaning. The customer uses this in recording context and wanted to focus on making the amp as noise free as possible.

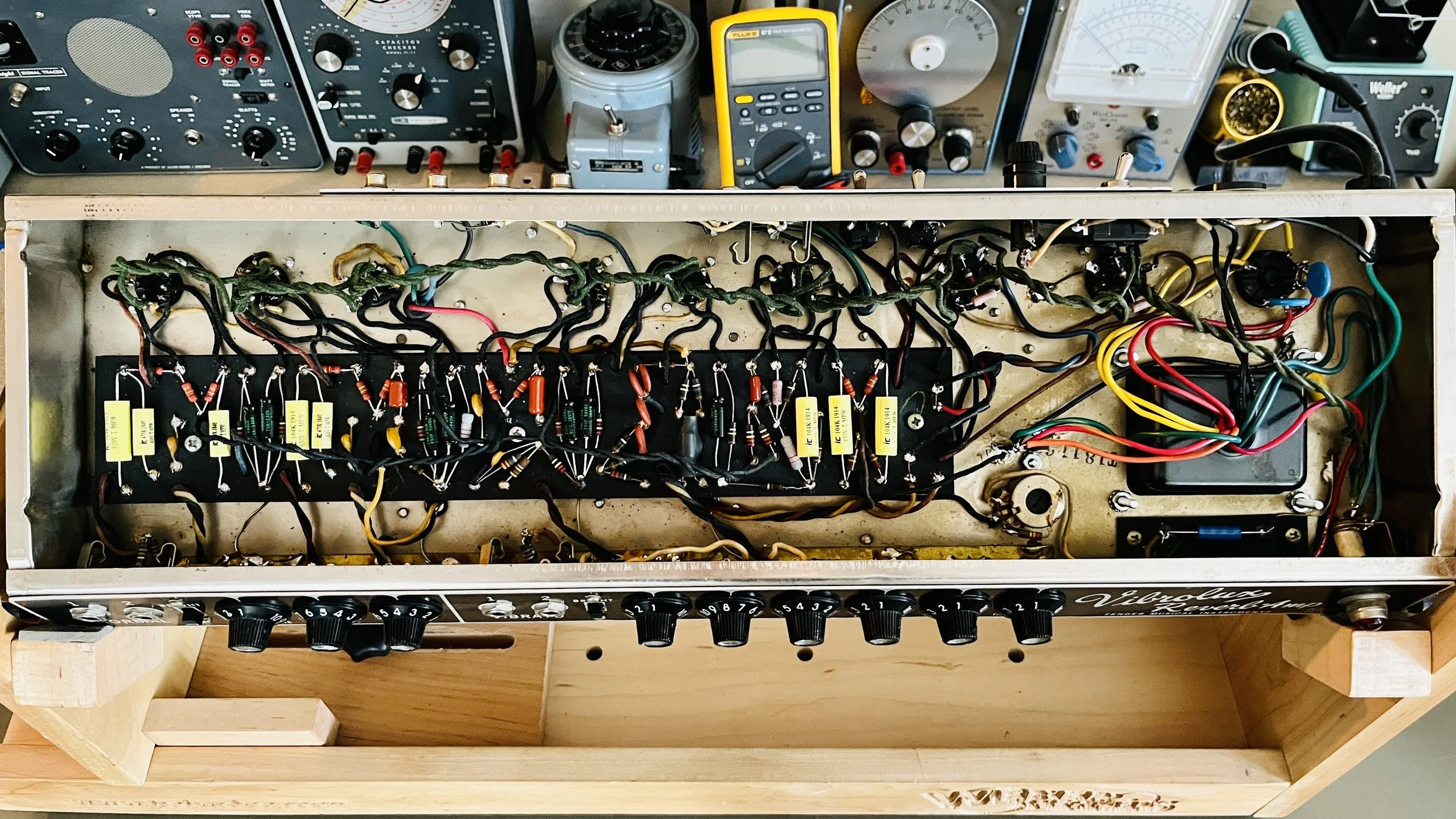

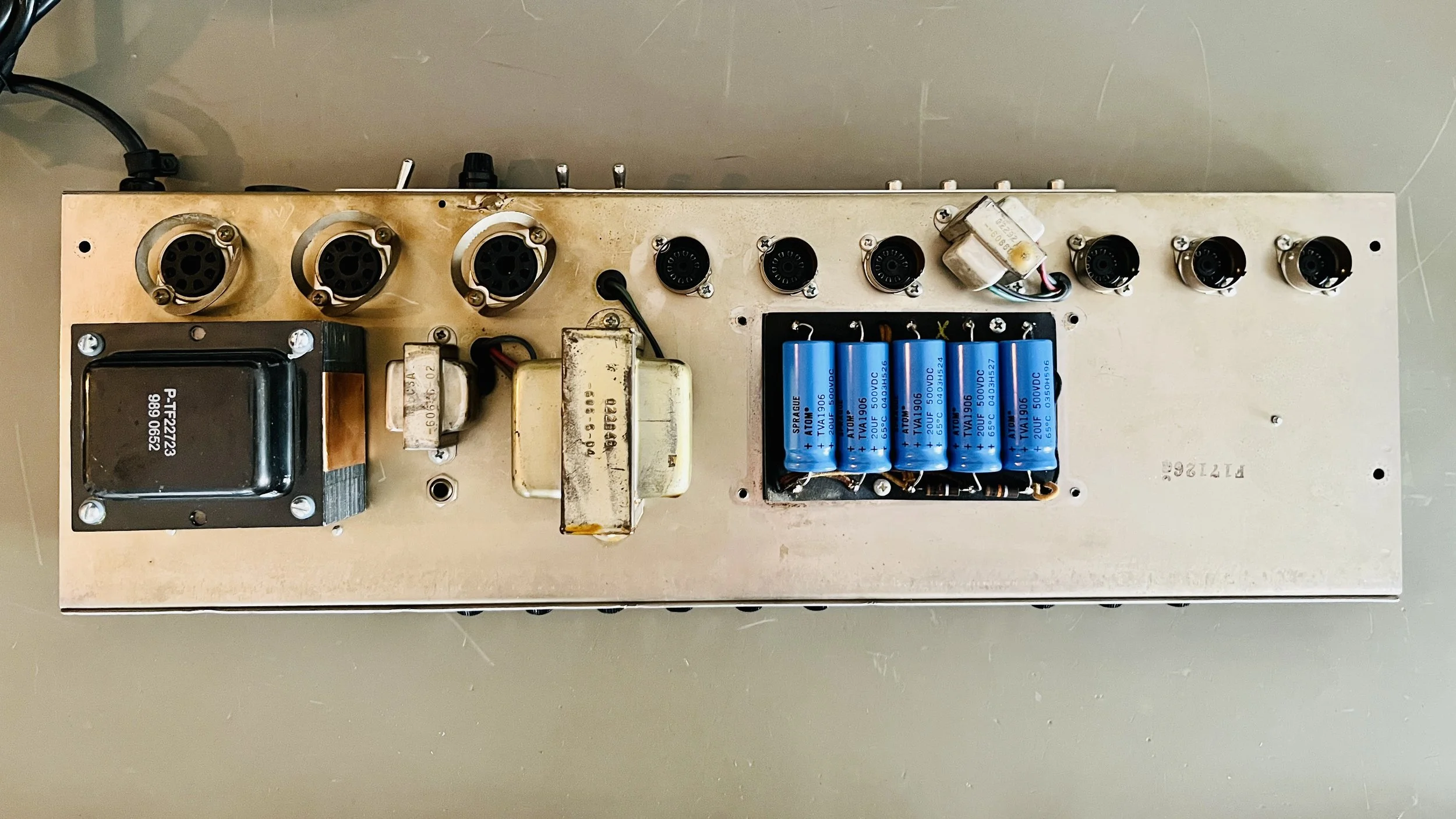

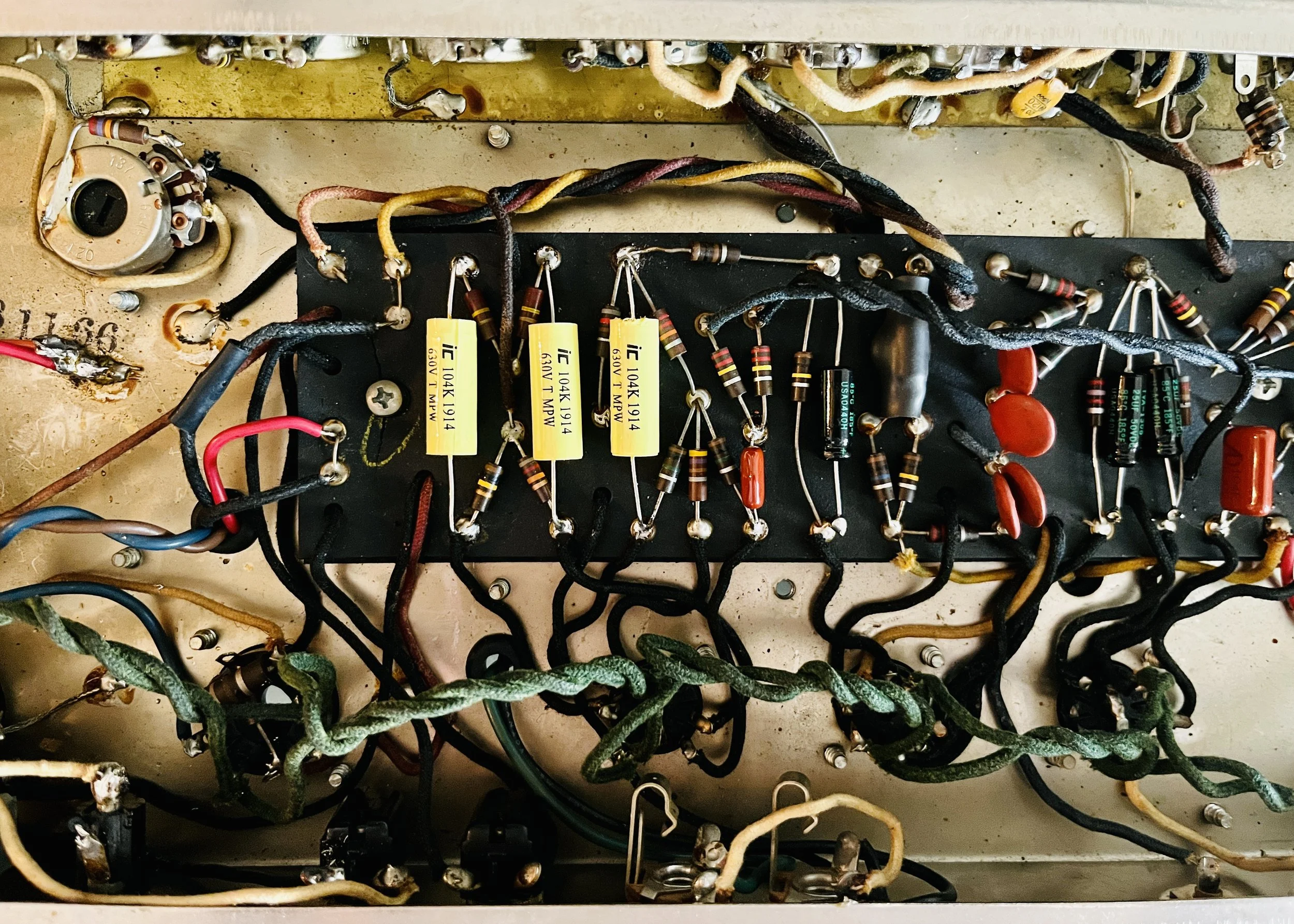

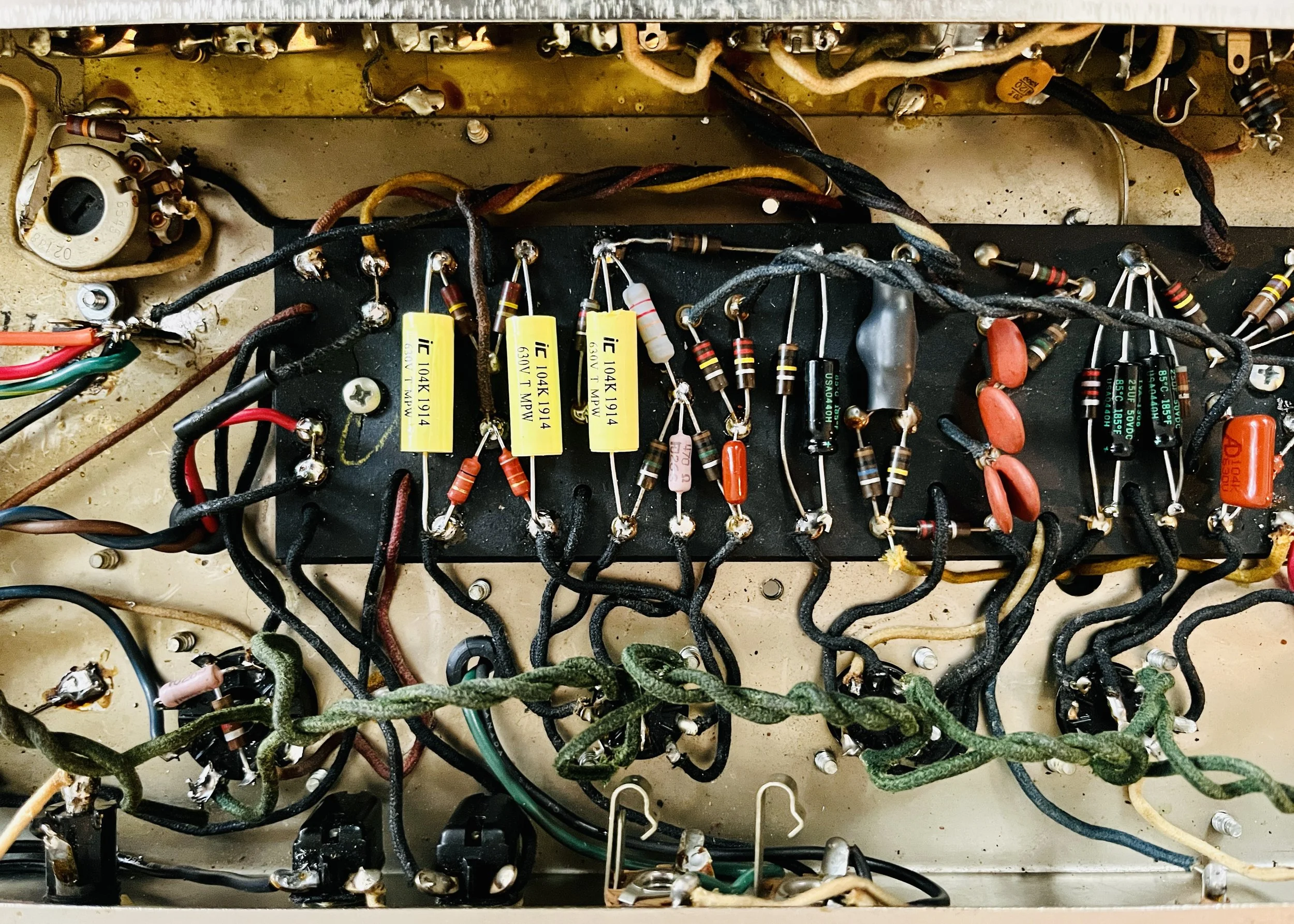

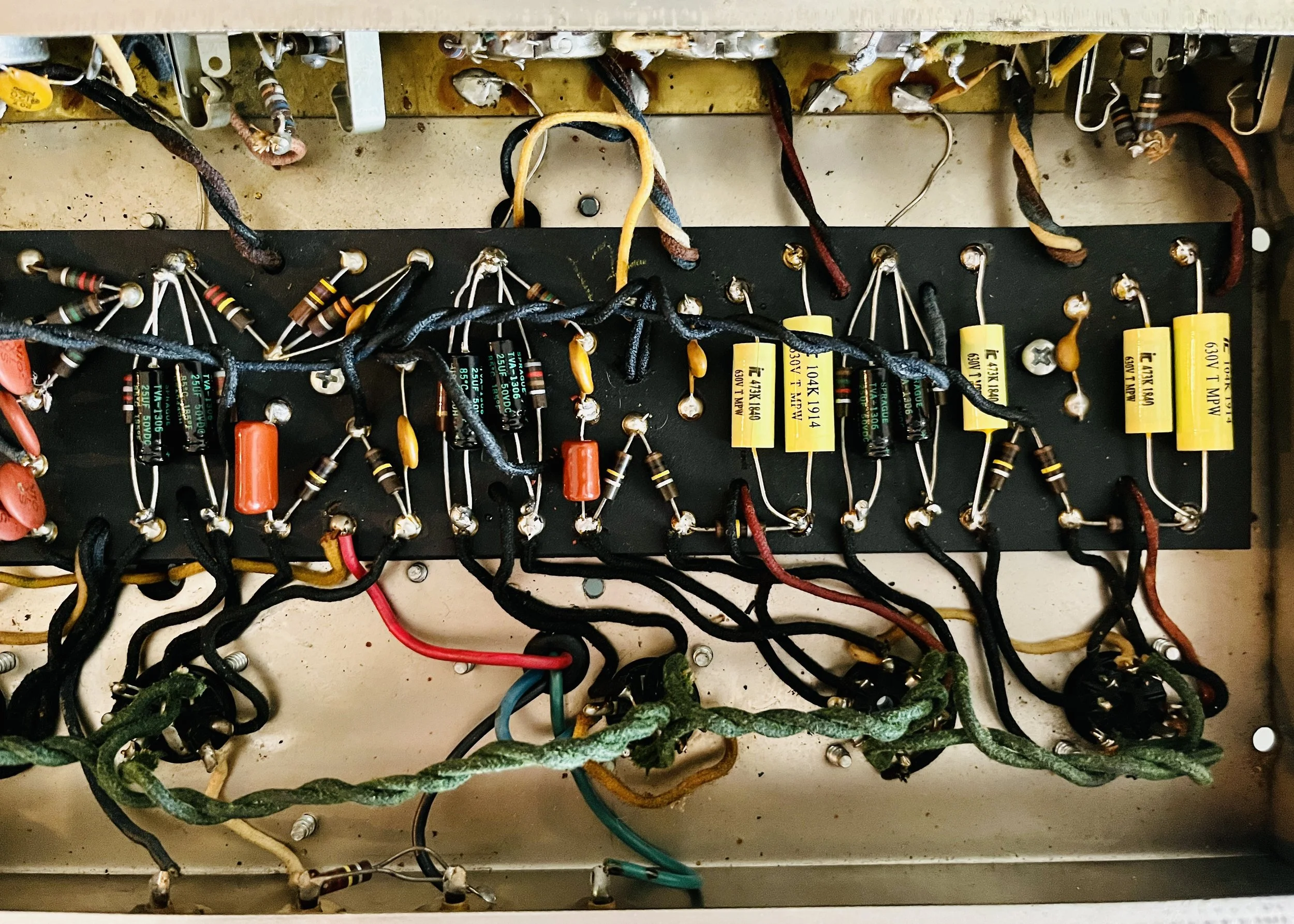

The amp was given a partial restoration to complete the previous one from years earlier. All filter/bias caps (the bypass caps were all good and left in place) were replaced with upgraded voltage and temperature rated MOD/Vishay brand electrolytics. The initial two electrolytics in the filter and standby circuits were replaced with two MOD brand 70uf 350v units and two 220k 2 Watt Metal Oxide Resistors in a balanced series topology. This was done in order to deal with the high voltage (approx. 500VDC) during standby. Originally the amp was made with caps that had 450VDC max ratings, and current electrolytics top out at 500VDC so the first filter stage had to be modified to account for this. This stage now can accommodate the standby voltage with a combined circuit capacitance of 35uf at 700VDC max voltage - as close as possible to the original 32uf parallel circuit spec.

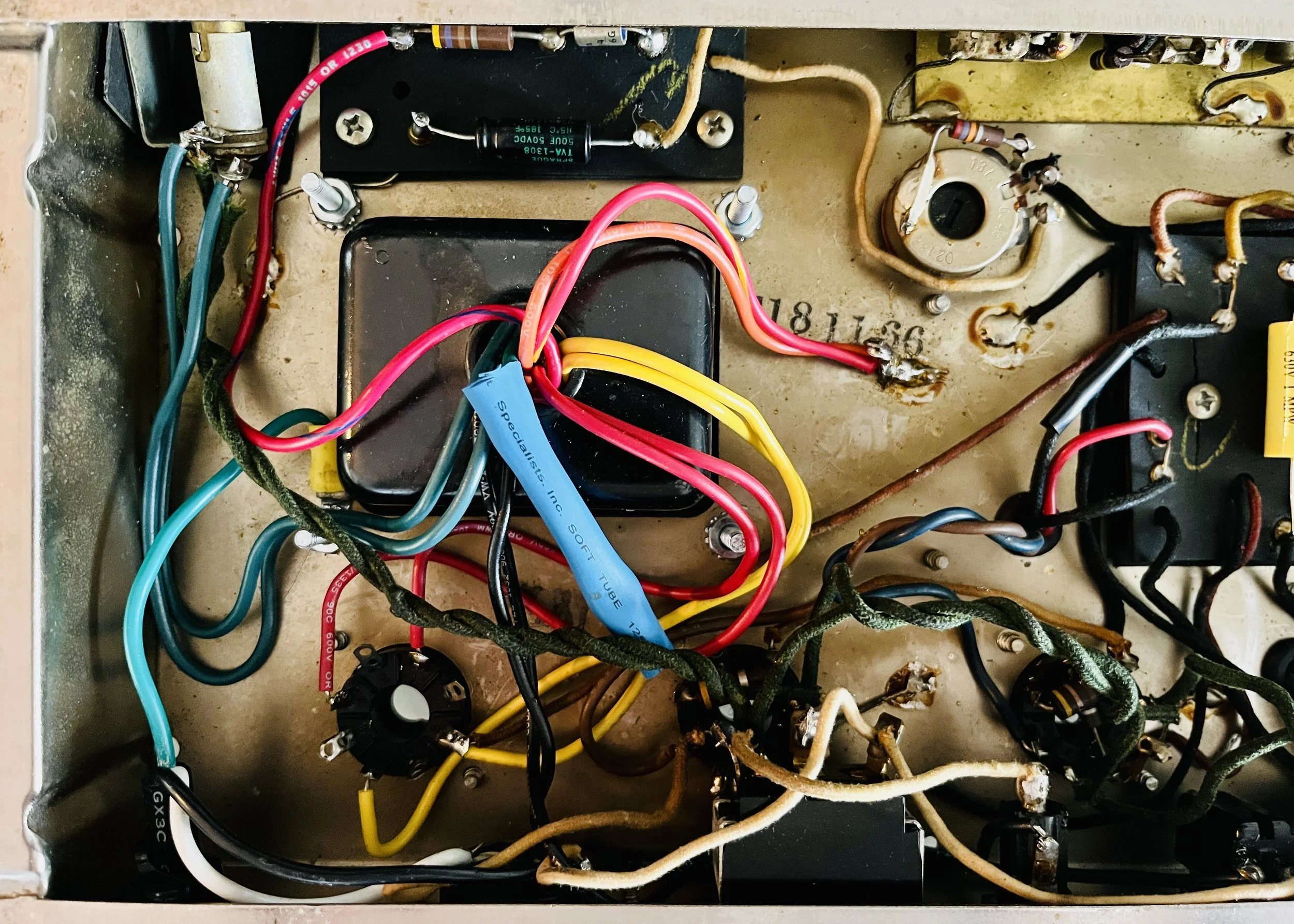

New 2 Watt Metal Oxide power dropping resistors were installed for better reliability and lower noise floor. The cathode resistors for V3 and V6 were replaced with 2 Watt Metal Oxide/3 Watt Cement type units due to heat damage and for preventative maintenance. 1/2 Watt Carbon Comp resistors were used to replace the original power tube grid stoppers due to heat damage - carbon composition resistors in the signal path preserve the collectors value and vintage tone of the amp. All plate resistors were replaced with 2 Watt Reduced Mass Metal Film type units for preventative maintenance and reliability. All screen resistors were replaced with 3 Watt Cement 470 ohm type units for same reasoning. 01uf 3000v Ceramic Disc Capacitors as well as 1N4007 1A 1000V Diodes were used to mod the rectifier circuit to make the amp as noise-free as possible. A new Carling SPDT switch was used for the disconnected Ground position. The one present was enormous and the heater lines were dangerously close to the AC input, which is also terrible for the noise floor. The replacement Power Transformer, which was a good quality make and the correct model, was wired incorrectly by the previous tech - the center tap for the heater lines was left disconnected and heat-shrinked, this meant that the heater lines produced an insane amount of 60-cycle hum that made the amp unusable in any real playing context. This circuit was properly re-wired. In an effort to eliminate noise further, the first filter cap's negative lead was connected to the main chassis ground point along with the center taps for the PT.

The original tubes (a mix of NOS and new) tested good, although the V4 reverb recovery tube was replaced for tonal reasons. This was the final lineup: V1/V2/V5= RCA 7025, V3 = JJ 12AT7, V4 = JJ 12DW7, V6 = RAYTHEON 12AT7, V7-V8 = JJ 6L6GC Matched Pair, V9 = JJ GZ34. The 6L6GC’s Fixed Bias was set to %50 Class AB Plate Dissipation with a B+ of 445VDC. The 12DW7 was used to lower the reverb noise floor and make the reverb control more usable. Originally the reverb effect was quite hot due to the amp having a modern replacement tank. The tank, which was made by MOD, is good quality but they can often be a bit strong in their intensity. The tube sockets were all re-tensioned and treated with De-Oxit to remove/prevent corrosion. The pots were sprayed out and the amp was cleaned inside and out. New chassis strap screws were installed as the originals were bent, rusted, and stripped. A rare example of a mid-60's Vibrolux Reverb.