1986 Marshall JCM 800 4104

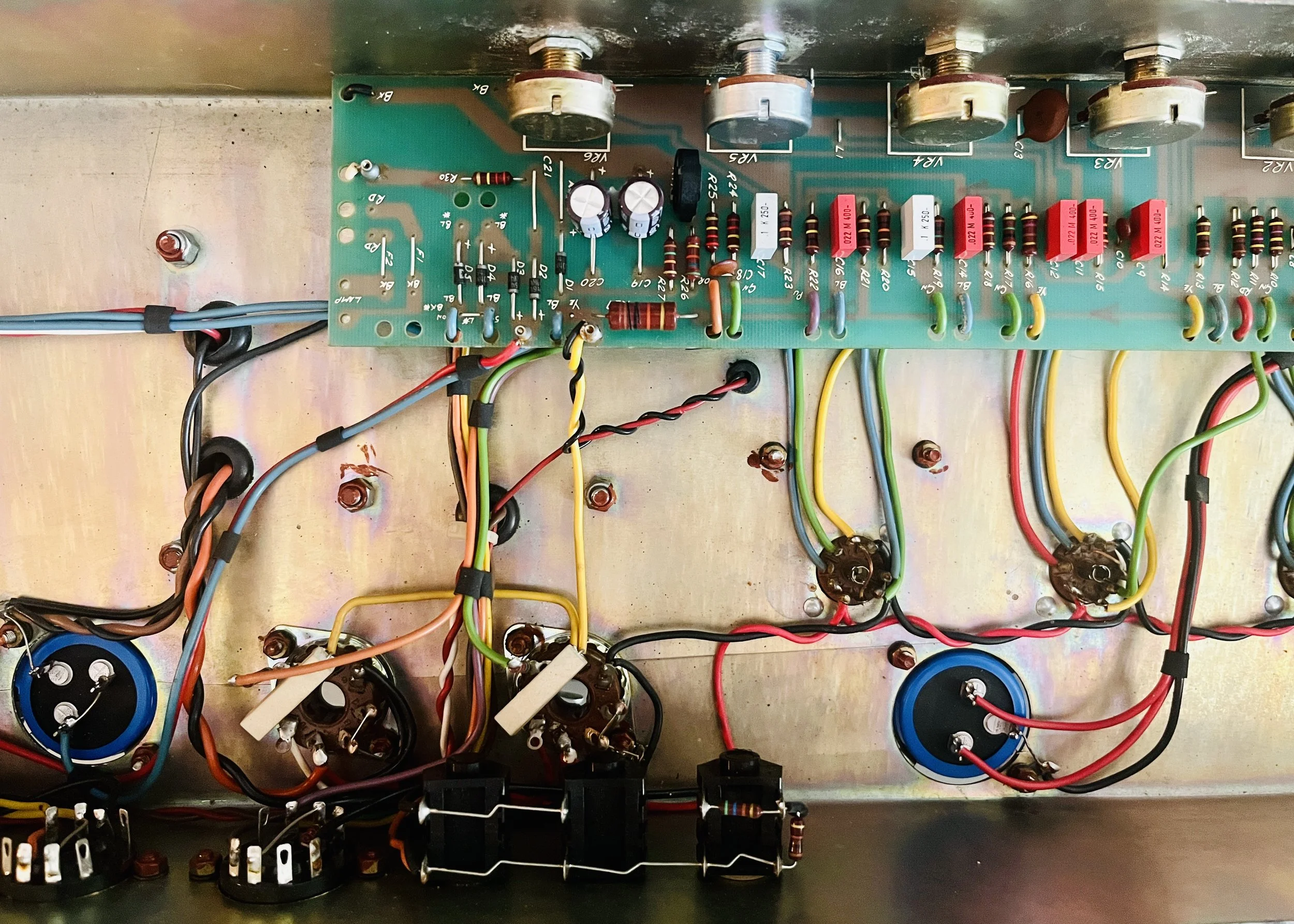

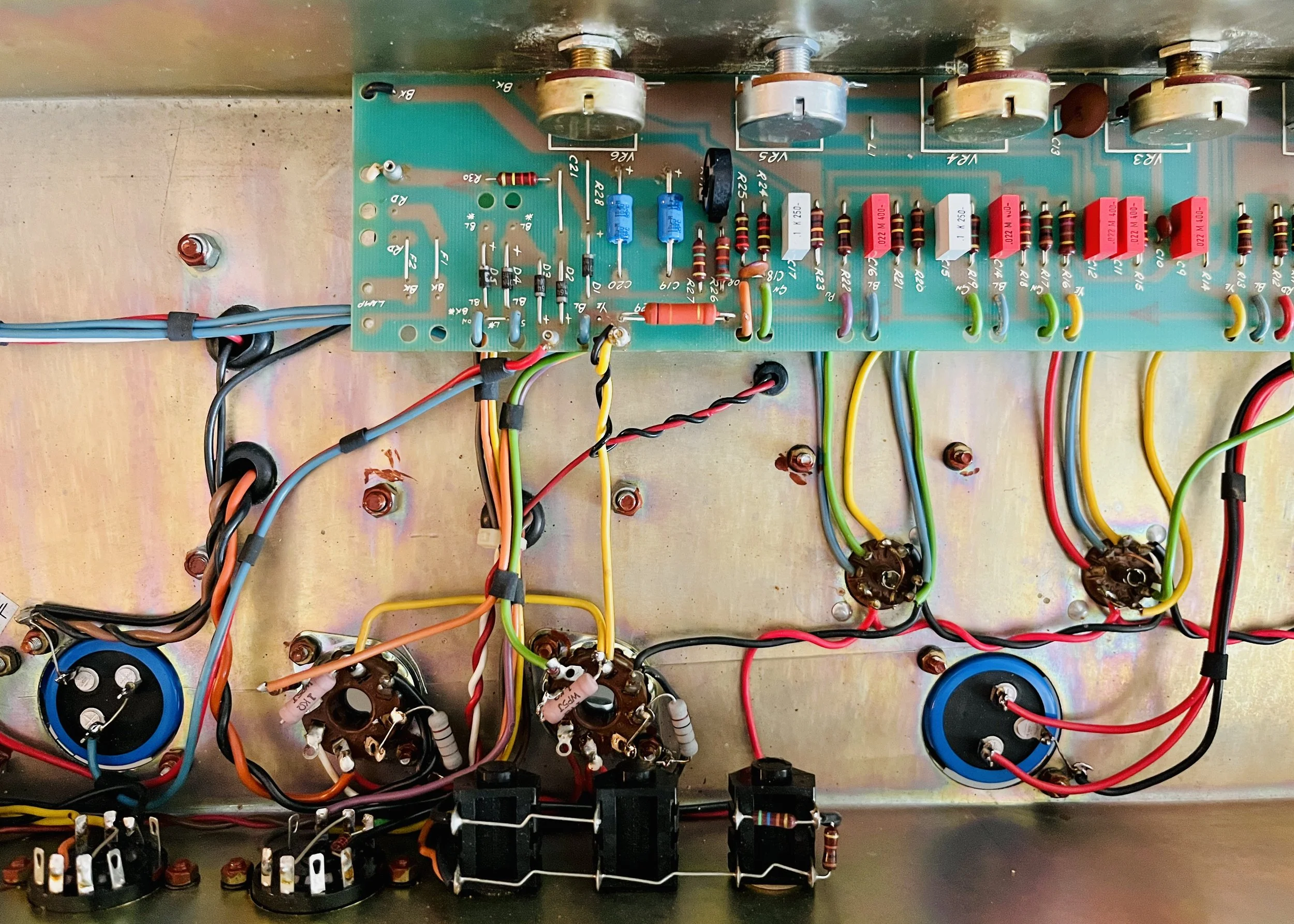

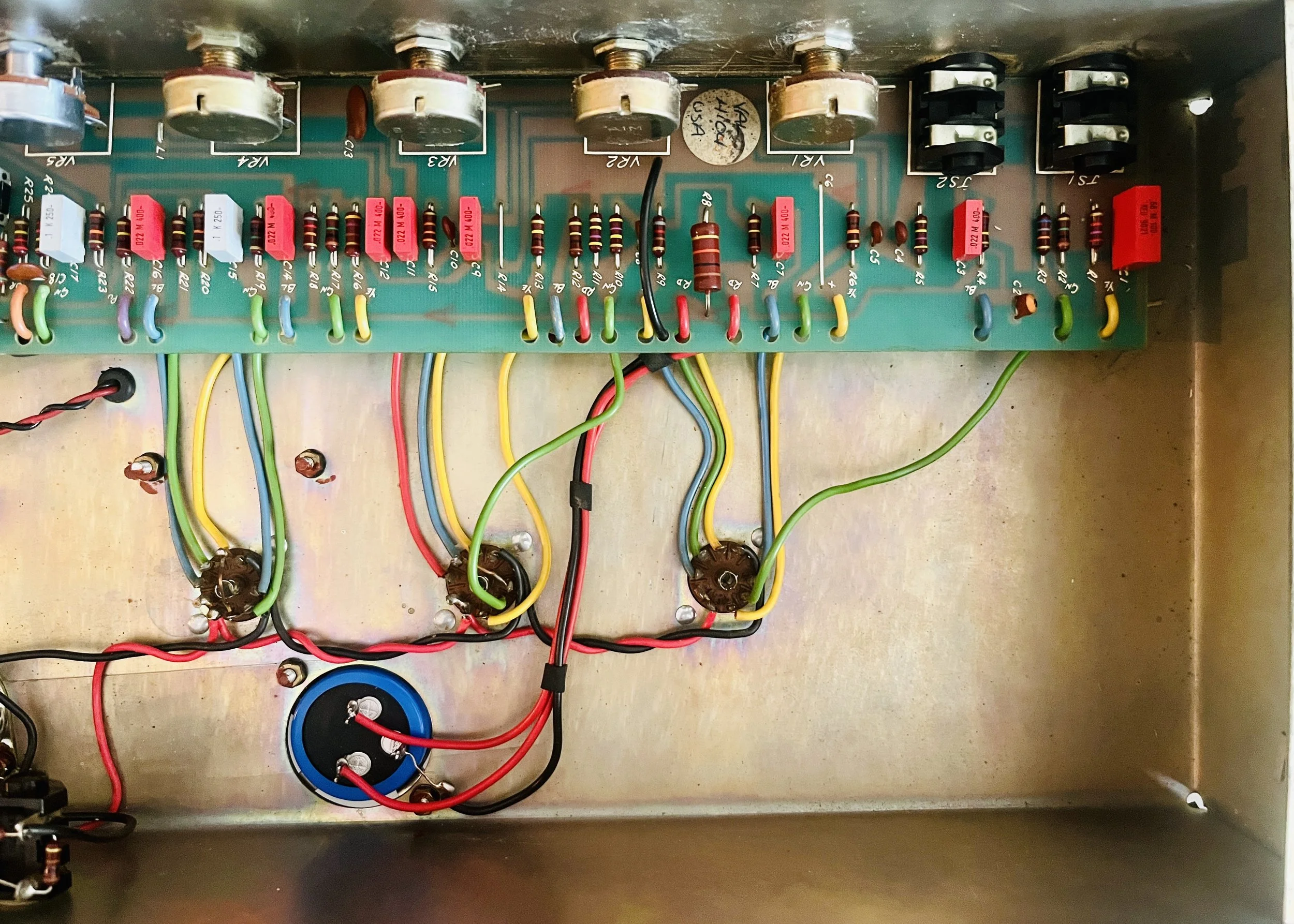

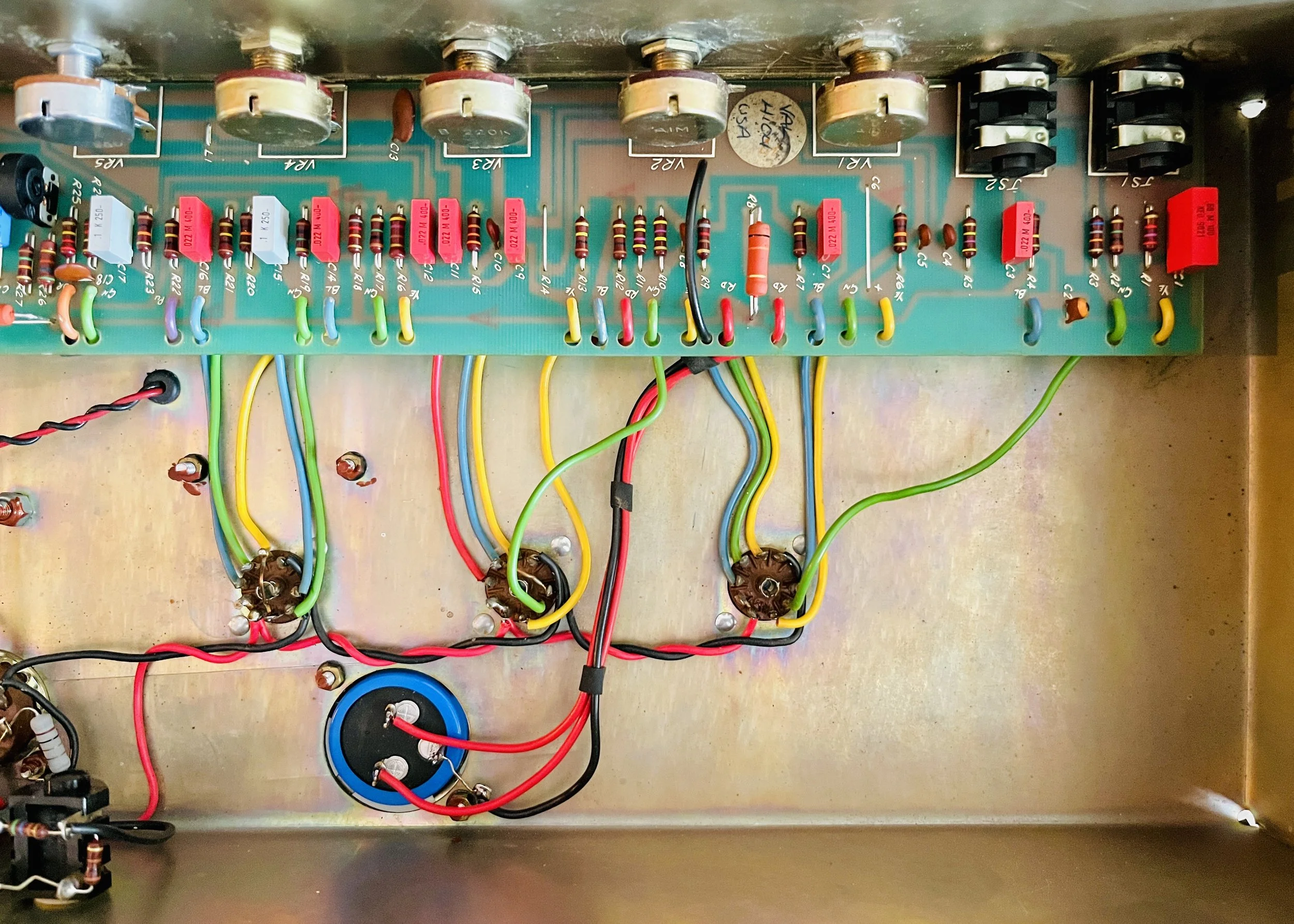

The 4104 version of the famed JCM 800 is a 2x12” 50 Watt combo that provides that classic JCM 800 sound in a smaller more compact unit. This 4104 was made in 1986 and has a few changes from the earlier JCM 800 models. The front panel has the updated horizontal input jacks rather than the vertical input jack arrangement previously used. This is just a superficial aesthetic change, but it signifies that Marshall had changed the circuit construction within to use less hand-wiring and more PCB mounted parts. The change from vertical to horizontal input jacks (and construction styles) occurred around 1985, and was done in order to cut costs in an increasingly difficult market for products made in the USA and UK. The potentiometers would now be directly mounted to the PCB rather than to the chassis with flying leads, which critics argue make these models more difficult to repair and reduces the resilience of the amp from damage. For the 100 Watt models like the 2203 and 4103 Marshall also reduced the number of electrolytic capacitor cans in the power supply resulting in much less filtering and therefore a noticeable change in sound quality. These amps do not hold up as well at high volumes and the general consensus is that they sound harsher, grainier, and lack the punch of of the pre-1985 models. Many people love these later models and argue that they sound different but definitely not inferior, in fact a lot of the famous guitarists associated with the JCM 800 use these models exclusively. This larger change to the power supply however did not affect any of the 50 Watt models, so the 4104 that we have here sounds the same as the vertical input versions. Notable users of the JCM 800 include: Ian Mackaye, Tom Morello, Slash, Larry LaLonde, Billy Corgan, Zack Wylde, and Kerry King.

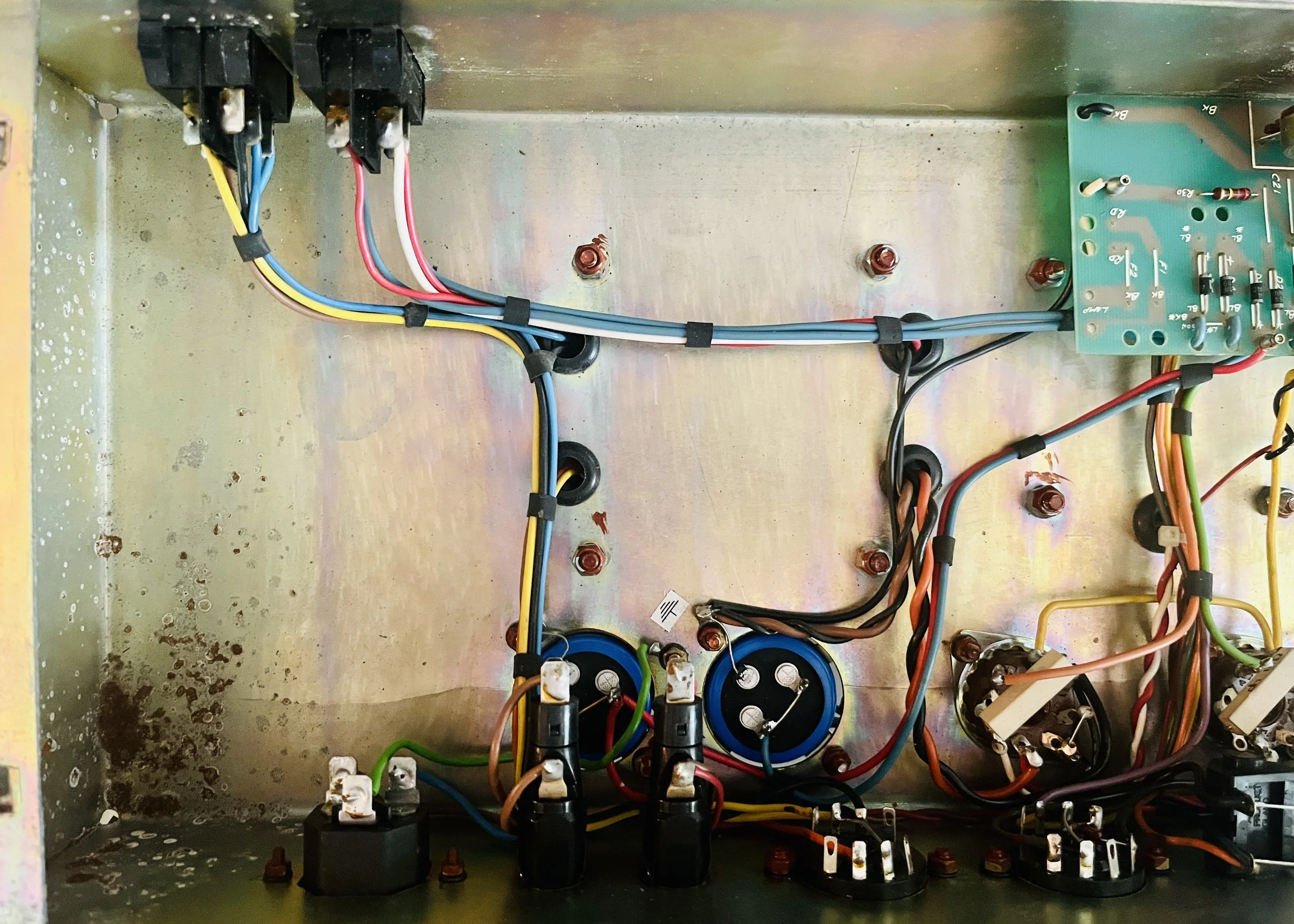

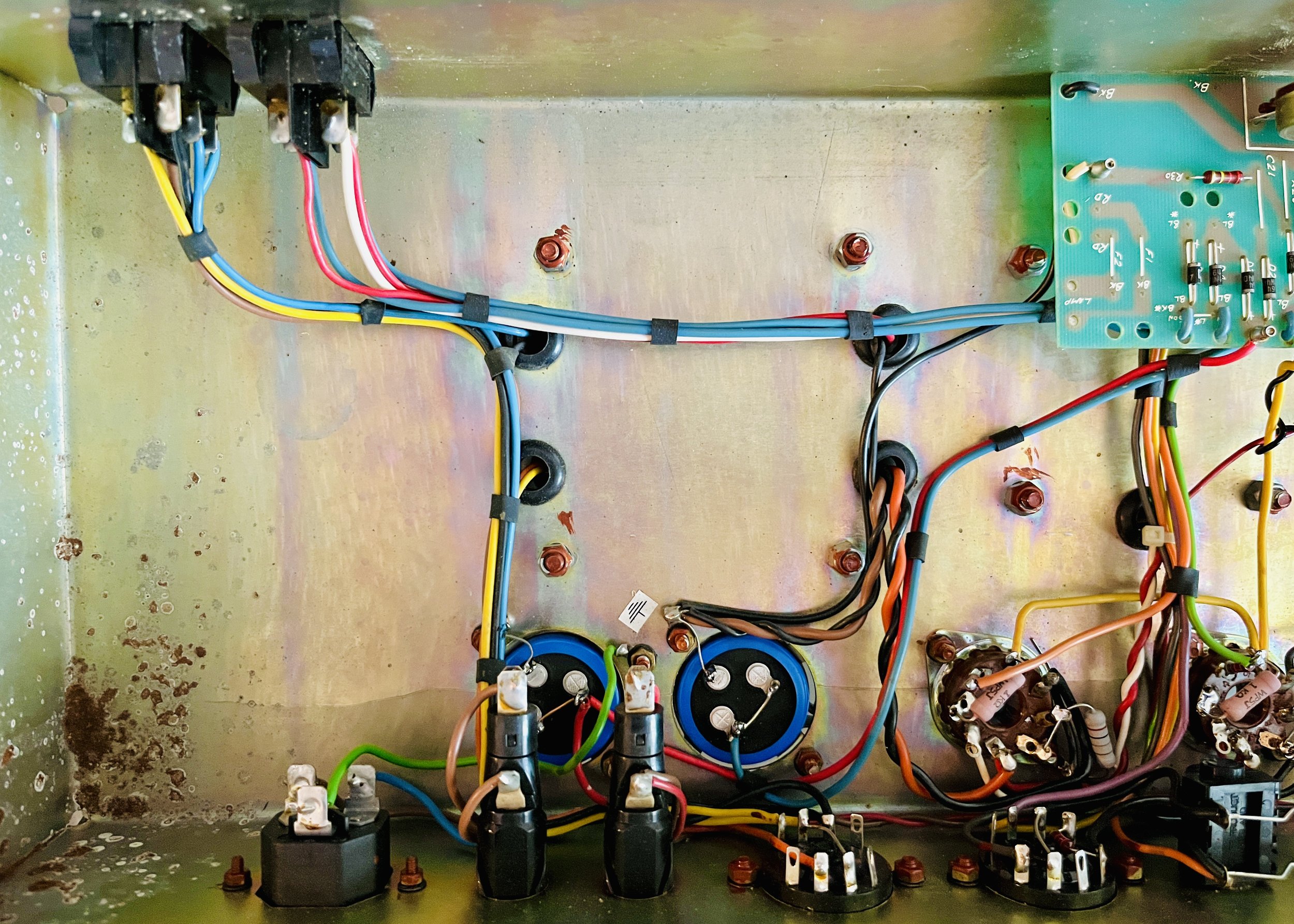

This amp came in to to the shop having already been restored, however a number of important pieces of preventative were left undone and there were also some blatant mistakes. It needed new power dropping resistors, screen resistors, electrolytic capacitors in the bias circuit, solder joints re-done, fuses, hardware, and tubes. When it arrived it barely made any sound and there were huge amounts of hum and noise.

Solder joints connecting the filter caps to ground were found un-soldered and were causing the entire filter supply to intermittently be disconnected. This caused lots of hum, noise, and arcing. These joints were soldered in place. The electrolytic capacitors in the bias circuit were replaced with axial leaded Vishay brand electrolytic’s as the replacements that were in the amp were radial leaded and did not fit the construction style of the amplifier. The power dropping resistors were upgraded to 3 watt Metal Film type and the Screen Grid resistors were upgraded to 5 Watt Cement type units respectively. This was done because of heat damage and cracking. This also lowers the overall noise floor and provides better reliability. 1 ohm 2 Watt Metal Oxide resistors were installed on pin 8 of the power tubes to provide an easy way to check the bias and to shore up the weak metal wiring that was in place. A new 3AG Fuse was installed as the one present was the wrong value.

The amp was completely re-tubed with the following compliment. V1-V2 = JJ E83CC, V3 = SOVTEK 12AX7LPS, V4-V5 = TUNGSOL EL34 Matched Pair. I picked out this lineup specifically for this amp to give the best balance of tone, reliability, and low noise. The adjustable Fixed Bias was set to %66 Class AB Plate Dissipation with a B+ of 438 VDC. The tube sockets were all treated with De-Oxit to remove/prevent corrosion. New stainless steel chassis screws and back panel hardware were installed to replace the stripped out and corroded units present. All pots were cleaned and hardware tightened.